About FlexBlox Solutions

FlexBlox™ Solutions for erosion and stormwater management and other civil engineering applications features an innovative, permeable 3-D material.

This unique micro-architecture excels in its combination of porosity, strength-to-density ratio, continuous high-tensile matrix, and exceptional resistance to compression without requiring additional infill.

Solutions areas

The FlexBlox™ system offers innovative solutions in these areas:

- Ground Stabilization / Load Support Systems

- Slope Protection/Erosion Control

- Earth Retention Systems

- Seismic Energy Dissipation

- Bio-Sensitive Pipe Support

- Three-dimensional Elastic / Expansion Joints

FlexBlox installations are ideal for steep and difficult access projects where space, soil, drainage, transportation and environmental constraints prohibit implementation of more conventional soil stabilization techniques.

Ground Stabilization / Load Support Systems

Slope Protection / Erosion Control

In areas of low to moderate intermittent flows such as ditches and swales, the system’s open architecture allows roots to grow in all directions throughout the matrix for greater vegetative lock-up and stability against short-term flow events.

Auxiliary cabling/tendons may be incorporated to provide additional stability against gravitational and hydrodynamic forces.

Earth Retention Systems

The FlexBlox system’s structural properties are excellent for steep front-face vertical applications such as highway embankments, especially in challenging sites where subgrades are comprised of unstable soils and right-of-ways are limited.

Enhanced design flexibility and aesthetics are possible because of the porosity and potential for a completely vegetated face.

Seismic Energy Mitigation

The FlexBlox macro-architecture holds promise in decoupling a building’s structure from the shaking ground and reducing earthquake-related damage through several mechanisms. Learn more about Seismic Energy Mitigation.

Bio-Sensitive Pipe Support

Flextegrity’s material architecture presents the opportunity to design dynamic, resilient load support systems. Weight can be distributed over a larger area without impeding drainage in challenging environments such as permafrost, wetlands and sand. Our permeable icosahedral material would allow gradual infiltration with native vegetation. Learn more about Bio-Sensitive-Pipe-Support.

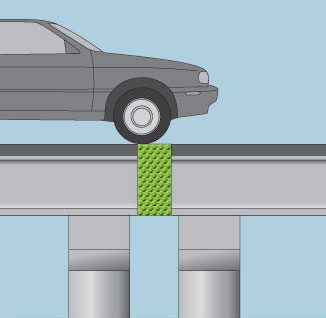

Three-dimensional Elastic / Expansion Joints

When engineered into bridges and other structures, Flextegrity’s advanced polyhedral materials have the capacity to bear substantial stress loads, yet absorb seasonal temperature- related dimensional changes.

Dimensional changes in multiple axes can be accommodated by the closely controlled elastic properties of the structural lattice architecture. These unique properties also offer enhanced robustness to earthquake movement/energy.

Product Benefits

FlexBlox Solutions brings these important advantages to project design and implementation:

- High strength-to- density ratio

- Omni-axial permeability for vertical and lateral drainage

- Customizable flexibility/stiffness gradients in three dimensions

- Pre-fabrication potential maximizes onsite installation efficiency

- Easily constructed in limited right-of-ways with less weight, lower environmental impact and reduced need for heavy equipment

- Aggregate infill is not required to achieve high resistance to compressive forces

- Multi-axial tensile ‘web’ creates superior resistance to shear forces

- Optimal frictional interaction with surrounding surfaces and infill materials

- Easily inventoried and handled

- Installation in any temperature or weather conditions

- Installations may be permanent or reusable/transportable

- No leachates

- Predictable, engineered material behavior

Learn more about FlexBlox and C6XTY material properties >>>