If we are going to manufacture new kinds of building materials that assist large scale earth science or military purposes, we are going to need new manufacturing strategies.

In the development of ships, airplanes, and cars, modular manufacturing practices have resulted in higher quality and enhanced features, while at the same time reducing costs and fabrication times. Yet this innovation is rarely practiced in architecture and civil engineering.

As Kieran and Timberlake rightly argue in their book, Refabricating Architecture: “Buildings continue to be assembled largely piece by piece in the field, in much the same way that the car was put together before the advent of mass production. Where is the evolution in building construction? Why is it that large parts of our buildings are not assembled as fully integrated major components, off site, in controlled factory conditions?”

To meet today’s design and construction needs, a wisely executed modular approach needs to replace the present model where huge numbers of small individual pieces are trucked in and laboriously cobbled together on an outdoor construction site.

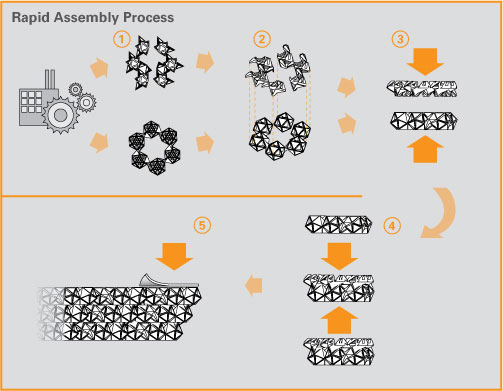

Flextegrity’s technology enables the ‘custom-knitting’ of lighter, stronger, safer structures. The capability for ‘uni-body’ construction of large, integrated, multi-functional ‘blocks’ in a controlled manufacturing setting ensures a higher level of quality assurance, and can significantly shorten on-site con- struction/installation times and processes.