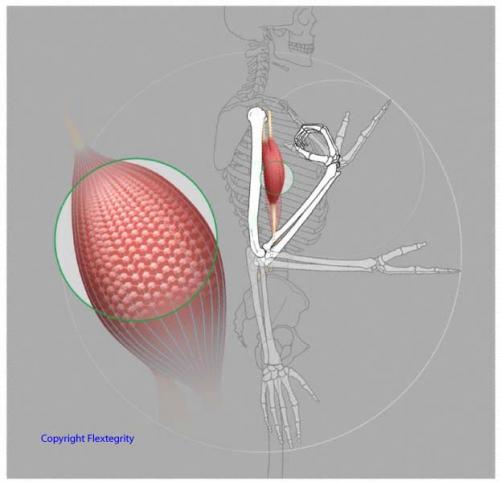

C6XTY has researched the new geometry to create materials and structures with respect to the weight. With the use of a Carbon 60 molecule, which is based on Buckminster Fuller’s observance. The ability to incorporate functional elements such as circuitry, conductivity, and lightning through Flextegrity technology. it has created one of the applications like Artificial Muscle.

Artificial Muscle / Bio-Materials are explicitly modified materials that can, under specific conditions, urge stem cells to change into bone cells. To do this, researchers actualized an alleged shape-memory polymer in stem cell look into.

Stem cells are known for their capacity to transform into a wide range of sorts of a cell, be they muscle cells, ligament, or bone cells. Much the same as the body; they are a piece of stem cells sense what occurs around them and respond as needs to be. For quite a long time, specialists have been finding out how to control this separation procedure by changing the environment of the cell. The information procured is as of now being utilized in the research of designing the tissue, as it were, to produce substitute materials that reestablish or keep up harmed natural fabrics. In any case, most research has been done on static frameworks.

Finding a new method

The analysts took a polymer sheet that demonstrations like an artificial muscle. The sheet has the strange property in that it is prepared to transform when presented to rehashed temperature changes reversibly. The specialists just formed a framework onto the underside of the sheet and customized it to extend as the temperature went from internal heat level (37.67 °C) to 10 °C and to contract when re-warmed. They, at that point, seeded the sheet with undifferentiated cells and deliberately watched the changing state of the gridded sheet and cells. With the assistance of this “fake muscle,” the researchers could utilize one physical sign – the temperature change – to all the while imparting a second mechanical sign to the undeveloped cells. With these synchronized improvements, it is conceivable to urge the undifferentiated cells to transform themselves into bone cells.

Polymer actuators

Polymer actuators are materials that produce mechanical work in response to external stimuli. The automatic input is formed by the basis of temperature, PH variation. In the context of providing mechanical variation such as a range of strains and stresses, tissue engineering applications, etc.

“Our polymer actuator sheet has a supposed shape-memory work. In our investigations, this permits it to act like a transducer, with which we can successfully teach the cells to do as we wish. We found that the adjustments in temperature, joined with the continued extending movement of the film was sufficient to urge the stem cell to be identified into bone cells.”

Complex bone breaks in the potential application

“The customized polymer sheets could, for instance, later be utilized to treat bones broken so severely that the body can’t fix it without anyone else. The new cells from a patient’s bone marrow could be refined on the sheet and adaptively fold over the bone during activity. The already “prepared” cells could then straightforwardly fortify the bones.