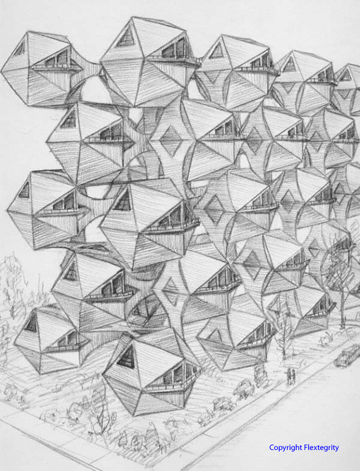

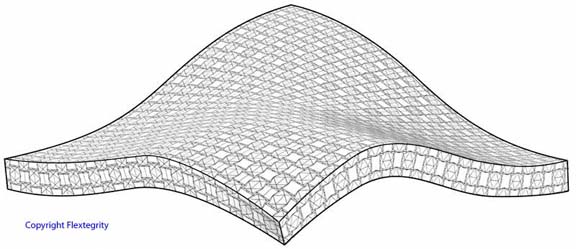

•The Flextegrity array is omni-extensible—the repeating pattern of the geometry may be extended in all directions to achieve material dimensionality that is not limited by the ‘natural’ dimensions of the raw materials from which it may be manufactured. In addition, an existing array can be increased in size by connecting additional discrete polyhedrons to existing polyhedrons with additional connections, without requiring other modifications to the existing array.

• Like the strongest “traditional” materials (wood, steel, and reinforced concrete), the Flextegrity geometry has significant strength both in tension and compression, in addition to shear and torsion, affording greater freedom and efficiency in design and use.

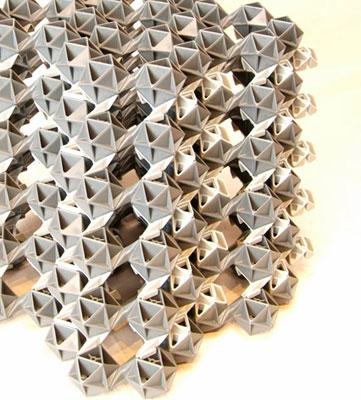

• Strength-to-weight ratio is inherently high even before material choice. “Open” yet strong geometry efficiently reduces weight, material requirements, and transportation costs.

• Material applications of the Flextegrity technology are permeable without sacrificing toughness.

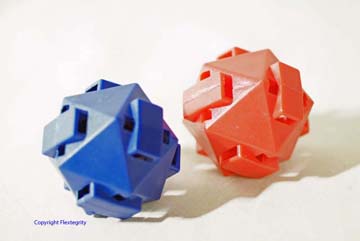

• Material/product design can be implemented in virtually any category of materials (plastics, metals, textiles, wood products).

• A wide range of non-homogeneous characteristics can be custom-engineered within a single product even when manufactured of a homogeneous material, making product performance local and site-specific. Omni-directional control of material and size also enables customized “hybrid” solutions using components of differing raw materials.

• Multi-layer, multi-component material structures are possible without mixing materials or binding agents, which significantly enhances environmental friendliness and recycling potential of component materials.

• Open 3-D Flextegrity geometry creates regular, stable matrix with increased internal “active” surface area, capable of being “loaded” with functional elements (i.e., chemical “beads,” wired or wireless address-able locations, circuitry, lighting/heating elements, solar cells, seeds, phase-change materials, barrier layers).

• The capability for ‘uni-body’ construction of large, integrated, multi-functional structural components in a controlled manufacturing setting ensures a higher level of quality assurance, and can significantly shorten on-site construction/installation times and processes.