Flextegrity: A Problem-Solving Technology

Deploying Nature’s own Geometry

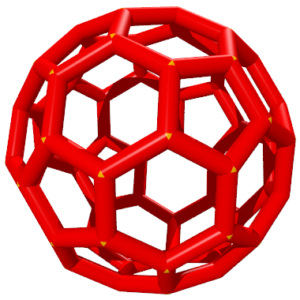

C6XTY deploys nature’s own geometry to create materials and structures, that are both strong and lightweight. C6XTY utilizes the familiar shape of the soccer ball, which is also known as a Fullerene or Carbon 60 molecule. The unique geometry is inherently stable making it well suited for carrying loads in compression, much like a ball bearing.

When the ‘Bucky’ balls are ordered in a lattice-like arrangement, entirely new categories of materials and structures are possible. Solutions can be manufactured at any scale, from almost any substance for a wide variety of applications. Applications can vary from muscle replacements and computer memory to retaining walls, housing, and bridges.

Watch an Interview with Sam Lanahan, the inventor of C6XTY

Tomorrow’s infrastructure will require 4-D printing technologies to build entire transportation networks and water systems. 4-D printing is coupled with artificial intelligence, to comprehensively address the demands of the built environment. This infrastructure will be purposely constructed to optimize strength and minimize the use of materials.

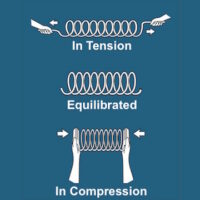

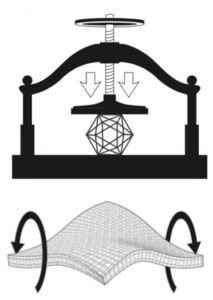

C6XTY’s innovation is based on Buckminster Fuller‘s observation that compression can be thought of as ‘islands’ in a sea of tension. Tension and compression can be arranged in a uniform lattices [Snelson, Fuller, Lanahan]. We know intuitively that balls (spheres) act in compression, as when materials are compacted between our own two hands. We also observe that strings and wires are inherently strong in tension when we try to pull both ends opposite one another.

What is less obvious, is that these two forces are everywhere operating simultaneously on scales both small and large. Tension and compression- the yin and yang of structure – are inseparable. While they can be thought of as being in opposition to one another, they can also be tamed into a harmonious relationship.

That is accomplished through triangulation. Compression is triangulated in tension. That is the key, because stable structures are triangulated. This arrangement of tension and compression, results in a uniform lattice optimized for the specific application.

C6XTY and Carbon 60’s Shape

The structure of the Carbon 60 molecule is comprised of 20 hexagons and 12 pentagons. C6XTY’s patent pending innovation is based on the discovery that the geometry of the soccer ball, can be further subdivided into 6 identical components called a “C/6t”. These components represents 1/6th of the total needed to comprise the whole.

C/6t

A single C/6t is made from a simple arrangement of 2 pentagons and 2 hexagons, which are formed or molded to the radius at the desired scale. The C/6t’s are arranged at 90 degrees to one another as on the surface of the sphere. The assembled structure is inherently strong and lightweight.

This is accomplished in two ways: the spherical shape distributes external loads radially throughout the shell that comprises the surface and, as any substance or structure collapses in on itself -it gets harder and harder to compress.

C/6t can be made from many substances such as concrete, steels, biologics, to plastics and high tech materials. This extraordinarily simple component allows solutions to a great many problems, because these materials can now be manufactured inexpensively and in great volume. Material selection and scale would be determined by the application.

What is Flextegrity and what does it offer?

Conventional design paradigms are constantly being re-worked, because they are not based on optimal geometry. It is difficult to test new alternatives until they meet established building codes.

Flextegrity provides improved materials for design and engineering innovation. Recent catastrophes on all continents point to the need for structural materials, that will perform well under increasingly extreme stress conditions. Our advanced materials anticipate emerging needs in design, and offer comprehensive solutions to real-world problems.

Flextegrity’s advanced icosahedral architectures address a number of increasingly complex material requirements. Flextegrity provides structural materials for architects in diverse fields, from disaster-resistant housing to environmentally mandated geotextile solutions.

The foundation of Flextegrity’s intellectual property is a unique and innovative icosahedron– based architecture for assembled structural materials. Our patent- pending geometry uses well-proven engineering principles in new ways, to leverage the inherent compression and tension forces of standard materials to their optimal natural performance.

Flextegrity’s Advantages

Superior Strength-to-Weight ratios and Predefined Flexibility and Stiffness

Specifically, Flextegrity geometries, from nano- to meso-scale, utilize polyhedral elements as compression members, and a proprietary tensile matrix to produce structural materials. These materials are omni- directional anisotropic and have superior strength-to-weight ratios. Their flexibility and stiffness characteristics, in every dimension, can be precisely definable in advance.

Higher Quality and Enhanced Features

In the development of ships, airplanes, and cars, modular manufacturing practices have resulted in higher quality and enhanced features, while at the same time reducing costs and fabrication times. Yet this innovation is rarely practiced in architecture and civil engineering.

As Kieran and Timberlake rightly argue in their book, Refabricating Architecture:

“Buildings continue to be assembled largely piece by piece in the field, in much the same way that the car was put together before the advent of mass production. Where is the evolution in building construction? Why is it that large parts of our buildings are not assembled as fully integrated major components, off site, in controlled factory conditions?”

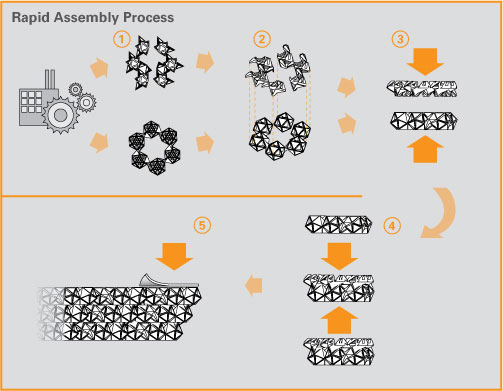

To meet today’s design and construction needs, a wisely executed modular approach needs to replace the present model where huge numbers of small individual pieces are trucked in and laboriously cobbled together on an outdoor construction site.

Flextegrity’s technology enables the ‘custom-knitting’ of lighter, stronger, safer structures. The capability for ‘uni-body’ construction of large, integrated, multi-functional ‘blocks’ in a controlled manufacturing setting ensures a higher level of quality assurance. It can significantly shorten on-site construction / installation times and processes.

Solution Examples

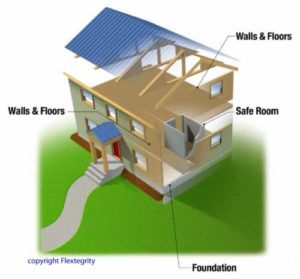

Disaster-Resistant Housing

Problem: The changing global climate brings more frequent, severe, and disastrous weather events that overwhelm conventionally built structures. Present day housing construction is driven by a short-term cost mentality and traditional uses of materials. It is only as strong as its weakest connection such as the point where rafters join walls and exterior walls intersect, making the structures prone to damage from earthquake and wind damage.

We continue to rely on the same materials and designs in hurricane-prone areas even though existing methods often fail to meet the overwhelming stress / force demands on structures. Yet building codes and property insurers’ regulations are becoming more rigorous as we speak. We need to re-think our designs and use of materials, to anticipate catastrophic events and be resilient in extreme conditions.

Solution: Comprehensive custom-engineered solutions, leveraging the unique and robust properties of Flextegrity materials. Tough, continuous web-like assemblies for retrofitting existing foundations and walls, could be factory-built to custom sizes and exact specifications.

In new construction, the structure is designed as a “whole” where the rafters and walls are of the same integral construction to create unprecedented resilience against novel external forces. The diverse design potential of Flextegrity materials, could allow for retrofitting and new construction of disaster-resistant structures, without sacrificing traditional architecture’s look and feel.

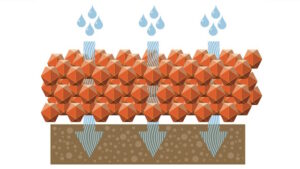

Water Run-Off Solution

Problem: Environmentally damaging water run-off is increasing as we pave our suburbs. Simultaneously, water quality is decreasing as current water control methods channel run-off directly into streams and rivers. The more we pave, the less opportunity for water to percolate through the soil before reaching the aquifers and rivers that provide clean water for our cities.

Sidewalks, as a familiar example, are relatively easy to apply but the material is impermeable, contributing to polluted run-off into our waterways. Paved surfaces present additional problems, as the material lacks any resilience and breaks under the pressure of a tree root. Successful repair is impossible—we are forced to jackhammer the problem, haul off the debris, and start over. Municipalities and contractors face an increasingly high bar of EPA-mandated stormwater control regulations, and are searching for versatile and effective solutions.

Solution: Meet demand for EPA-required soil stabilization and stormwater control products, that balance strength and durability needs with environmental requirements. Flextegrity will produce structural 3-D “geotextiles” that are load-bearing yet permeable. This will allow controlled drainage of stormwater, and natural percolation / de-activation of petroleum-based pollutants.

The assembled array can flex under stress, and the component parts are easily dissembled and reassembled for maintenance. Designers will gain the ability to create natural forms, that begin to look and behave more like the natural landscapes they replace. Soil stabilization fabrics, sidewalks and eventually, streets, can be constructed using strong materials that offer the benefits of permeability and ease of maintenance. Intelligent sensors, microelectronics and a variety of unique and responsive properties can be engineered into the material.

Lightweight, Flexible, Easy-to-Assemble Building Materials

Problem: Inflexible, heavy, non-integrated building materials. Age-old materials such as brick, steel, and wood don’t truly integrate with each other. They are abutted, bolted and otherwise coerced to coexist. Their inherent design forces us to build most structures using 90-degree angles.

But we only need to spend more time outside to observe that biological systems (the most supremely efficient in the structure and use of raw materials), do not use Cartesian coordinates to grow and sustain life.

Solution: FlexBlox, in initial development, will be the first flexible, permeable, structural material in the marketplace. Flextegrity’s geometry mimics natural structural efficiencies and can be integrated to form limitless iterations for landscaping, exterior and interior constructions, architectural motifs, and fencing. FlexBlox, a lightweight, flexible, easy-to-assemble material, will be equally appealing to the contractor and the home handyman.