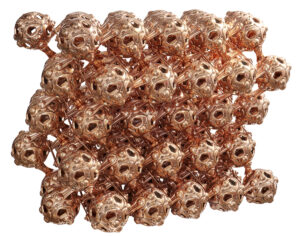

In this article we present Flextegrity’s patent – arrays that vary anisotropically, omni-topologically, creating myriad hybrid materials.

Arrays and lattices

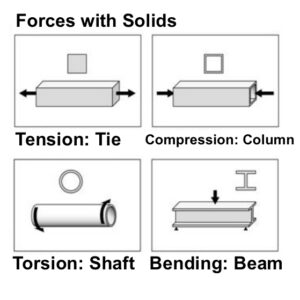

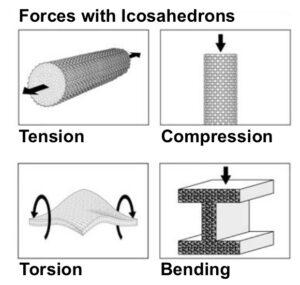

Micro-Structured Materials can be thought of as new ‘raw’ material resources, and combined with macro- molecular shapes to create hybrid materials. Arrays continue that hierarchical sequence resulting from combinations of materials, micro– and macromolecular shapes, connecting ligatures and the periodic ordering of space into lattices. The lattices can be organized into “bending” and “stretch” dominated types with further assignment of properties of axial strength and flexural stiffness (see Michael Ashby’s Materials Selection in Mechanical Design, p. 297-8, 363-370).

The normal state of the system is not “solid state” but a state of dynamic equilibrium. A corresponding multi-directional compression-tension network encloses accidental stresses wherever they arise. The tendency toward peripheral or localization of stress is replaced by prescriptive multi-directional stress equilibrium.

Anisotropic arrays

Flextegrity’s patents describe the arrays that vary anisotropically omni-topologically creating myriad hybrid materials. The materials themselves can be made of micromolecular cells aggregated into clusters of polyhedra.

A defining characteristic of Flextegrity’s material architecture is its anisotropic potential. According to the invention, interconnecting elements are used to tie icosahedral elements together along at least two and preferably three Cartesian coordinate axes, forming a structural ‘fabric.’ The term ‘fabric is used in its broadest sense to refer to a structure that

may be essentially entirely rigid, essentially entirely flexible, or may have any combination of rigidity and flexibility. The material of which the interconnecting elements are formed may be flexible or rigid, and the material of which the icosahedral elements are formed may be flexible or rigid.

Huge benefit is derived from being able to design and build a ‘micro-structure’ into the material to optimally fit a specific enduse application: The interconnecting network can be configured in a generally repeating pattern, but with tremendously

variable functional characteristics due to the ability to vary the materials and microdesign of connecting tensile elements.

If you wish to read more into depth, you may have a look at our Advanced Icosahedral Materials pdf here >>>